Robot guidance and traceability

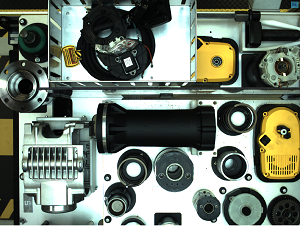

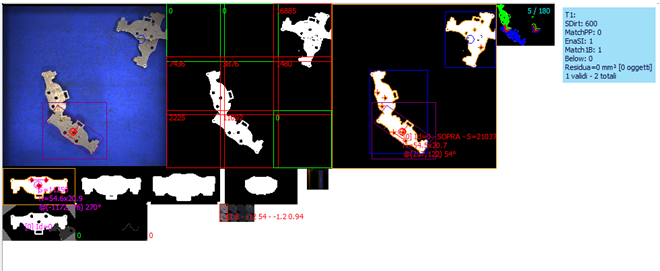

Platelet search

The vision system is used here as support for a line made up of two robots.

The position of the center of gravity and the direction of the plate are identified to allow correct gripping of the piece.

ZeroD is configured to work on different types and associates with each plate:

- the holes

- the outline

- the position of the center

- the grip position

- the rotation angle

- the distances between the holes